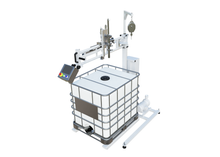

The DC-100 is a swing-arm semi-automatic drum & tote filling machine. It is also capable of filling pails on a pallet or on an add-on conveyor system.

Packages available specifically for your industry:

Coatings (paint, epoxy, urethane) Lubricants Agricultural Personal Care Food-processing Chemicals Cleaning Products Adhesives Contact us for customized quotes specifically for your application

Speak to our technical team about drum & IBC tote filling:

sales@paquip.com or call/text (904) 321-9363

See the DC series machines in action on ![]()

- 275 gallon IBC tote filling demonstration

- 55 gallon drum filling demonstration

- 5 gallon pails on a pallet filling demonstration

Capabilities, included standard

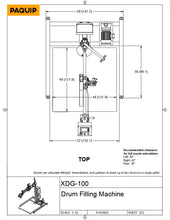

- Fill up to four drums directly on a pallet or one IBC tote

- Front-mounted touch screen controls with tilting enclosure

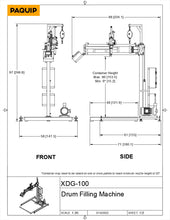

- Swing-arm design allows for precise positioning of the fill nozzle. Fill containers between 6 to 60” in height.

- Fill 60 seconds or less per drum, 5 minutes or less per IBC tote

Higher speed options available - 52” beam scale included (5,000lb max, +/- 1.00lb accuracy)

Optional 48"x48" platform scale available - 1.5” to 2" hoses to accommodate higher viscosity fluids

- Diving nozzle with foot valve, allowing for closed-top container filling from below the container opening. Standard nozzle dives 8".

Bottom-up and sub-surface filling with a longer nozzle lance available upon request - 7” screen for weight readout, setting weight target, and fill speed

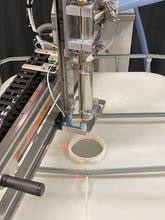

- Laser crosshair to aid alignment of the nozzle over container opening

- Variable fill speed with auto slow top off feature

- Sanitary fitting connections for easy hose swaps

Standard machine equipped with:

- 3.0HP centrifugal pump, with stainless steel case and impeller, sanitary tri-clamp fittings for easy cleaning and hose changes. (5HP or higher power pumps available)

- 7" Color touch screen

- 52" dual beam scale included allowing for easy access with either pallet jack or forklift

-

Powder coated steel welded frame

Stainless steel washdown or epoxy coated corrosion resistant frames available -

Fully adjustable nozzle position - Move the filling arm forward/back, left/right, and up/down to position the nozzle over each container. Fill up to 4 drums or 16 pails directly on a pallet. Switch to filling 275 and 330 gallon IBC totes quickly without any adjustments. The swing arm locks in position during filling.

Specifications:

| Fill Speed | Up to 60 CPH (Drums) Up to 12 CPH (Totes) |

| Measurement Method | Weight¹ |

| Fill Accuracy | +/- 1.00 lb (high-accuracy models available) |

| Viscosity Range | 1 - 600 cP with standard pump up to 50,000cP with air-operated pumps Additional options available |

| Fluid Particulates | Yes (small particulates <1/32”) |

| Fluid Temperature | Max: 120°F (49°C) Min: 32°F (0°C) (additional temp range available) |

| Fluid Supply Requirements |

Centrifugal pump: requires elevated fluid source or a vacuum primer to initially fill pump housing. |

| Corrosive Fluids |

Yes, depending on pump type (Plastic/non-metallic options and chemical-resistant epoxy frame coating available for highly corrosive applications.) |

| Foamy Fluids | Yes |

| Electrical Requirements |

208-240VAC 50/60hz, single phase, 18A for electric pump models 120VAC 50/60hz, 5A for air-operated pump models (Three phase and higher voltage available) |

| Air Requirements | 80 PSI @ 8 CFM |

* Fill speed may vary based on fluid & bottle characteristics

* Optional parts and upgrades may be required for compatibility with certain fluids

¹ With standard equipment, the net weight measurement is used as a proxy for determining filled volume and not for legal-for-trade weight measurements. Contact Paquip if your application requires NTEP-certified scale equipment.

Optional upgrades:

-

36" or longer Nozzle lance - for bottom-up and subsurface filling

-

Solid platform floor scale & scale accessories - Swap the beam scales for a platform scale with or without ramps.

-

Compressed air line clearing - easily change between products by air-clearing hoses

-

Various pump & hose options - customizable to suit your application, including with air-operated double diaphragm pumps

-

Explosive & flammable environments - Options for Class 1 Division 1 and Class 1 Division 2 available

-

Roller conveyor systems - Increase your capacity with a roller conveyor system with integrated pallet/IBC gating. Gravity and powered roller systems available.

-

5 gallon pail filling conveyor - Roller conveyor placed beside the DC-100 with pneumatic lid press. Increased pail filling accuracy to +/- 0.20lb.

-

Dye & chemical dosing - single and multiple dosing pump options

- Nitrogen dispensing, chemical dosing, remote operation, roller conveyor with gating, splash guard, fume extraction, and more