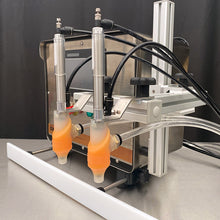

Designed specifically for quick and easy changing of fluids and bottle sizes. This is the perfect benchtop machine for small to medium sized production runs.

Our gear pump servo filling machines are extremely versatile with little-to-no setup between different bottle types, fluids, or volumes.

Speak to our technical team about bottle filling:

sales@paquip.com or call/text (904) 321-9363Limited Time Only - Free EZ-Adjust Nozzle Arm and 30" bottle fence included!

Availability - Contact us for current lead times, Ships free to US and Canada

Benchtop bottle filler videos

Quart bottle filling process

Load fluid, fill 12 quarts, then unload fluid for product changeover

Machine capabilities, included standard

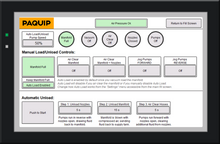

- Automatic loading, unloading, and air clearing

- Automatic self-priming

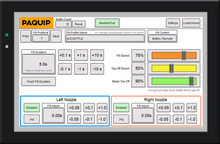

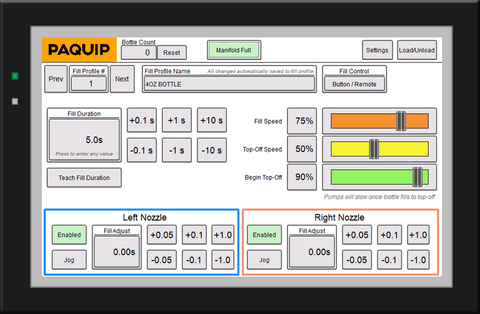

- 7" Touch screen controls

- Fast filling speed with slow "top-off"

- Filling settings memory, save up to 99 recipes

- Designed for quick swapping of fluids and bottle sizes. Ideal for small to large runs of many different products or container sizes.

- Fill from 1oz to over 1 gallon

- Easy to disassemble pump, manifold, and nozzles without tools

- Foot switch or control unit operation

- Push to fill or interval fill control

- Electronic "teach fill volume" function

Full color 7" touch screen controls

With a 7" touch screen, setting up your fill amount and speed is quick and easy, including fine adjustments per nozzle for fill level control. Save your fill profiles for quick changing between your different container sizes.

Nozzle options

Pictured: N100-R (left) for water and oil based products and most solvents, N100-S (right) for food products or applications requiring sanitary clamp connections.

Nozzle Option 1: N100-R Nozzle for water and oil based products and most solvents. Materials are well suited for most fluids and includes a 1/2" push-to-connect fluid hose connection. Wetted parts include photopolymer resin, Viton, Buna-N, nickel plated brass, and stainless steel

When ordering the FG-200 with the N100-R nozzles, we will include the matching composite polymer resin gears for the pumps as well as 1/2" OD polyurethane fluid hose.

Nozzle Option 2: N100-S Stainless Nozzle is ideal for food products and for any fluids pumped at an elevated temperature. Includes a 1" sanitary clamp fluid connection (1.984" OD flange connection). Wetted parts include stainless steel, polyurethane, and silicone.

When ordering the FG-200 with the N100-S nozzles, we will include PTFE gears for the pumps as well as 1/2" ID braided PVC fluid hose.

Materials, hoses, pump internals, and nozzles can all be customized for your specific application

Operation & Fluid Supply

The tabletop FG-200 filling machine can be operated in three ways:

- Start filling via pressing green start/stop button

- Start filling via remote foot pedal (pictured above)

- Start filling automatically at timed intervals

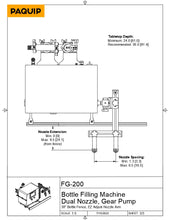

With our standard configuration, the FG-200 comes with sanitary clamp connections for the fluid manifold and will include a 90° 1/2" hose barb for you to connect your own hose.

Inlet fittings and geometry can be customized for your specific application

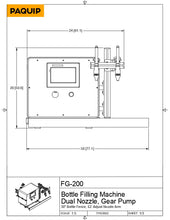

Standard filling machine equipped with:

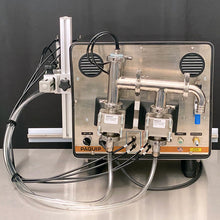

- Filler Control Unit, with (2) integrated gear servo pumps

- Dual nozzle with individual liquid fill level adjustment

- 7" Color Touch Screen

- Remote foot pedal

- Supply manifold - sanitary clamp stainless steel construction with 1" hose barb connection

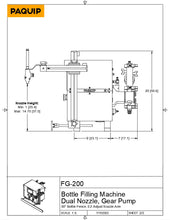

- Fully Adjustable Nozzle Position - Adjust the nozzles up and down to fit any bottle size up to 13" high (additional height available upon request

- Push-To-Connect hoses for both fluid flow and pneumatics. Easily change out fluid hoses without tools! (default configuration for N100-R is Push-to-Connect, default for N100-S is hose barb. Either nozzle option can be configured for PTC or hose barb upon request).

Filling specifications:

| Fill Speed | Up to 1,200 CPH (4oz Bottles) |

| Flow rate (per nozzle) | Up to 1.5 gallon/min |

| Viscosity Range | 1-5,000 centipoise |

| Fluid Particulates | Not recommended |

| Fluid Temperature | N100-R Max: 100°F (38°C) N100-S Max: 150°F (66°C) Min: 32°F (0°C) |

| Corrosive Fluids | Not recommended with standard configuration, contact us for options |

| Foamy Fluids | Yes |

| Electrical Requirements | 120VAC 50/60hz, single phase (240VAC available upon request) |

| Air Requirements | 80 PSI @ 3 CFM |

Fill speed may vary based on fluid & bottle characteristics

Optional parts and upgrades may be required for compatibility with certain fluids

Optional upgrades:

-

Stainless Steel Nozzles - For food grade or high temperature fluids, available upon request. Plastic nozzles for corrosive products also available.

-

EZ Adjust Nozzle Support - Easily adjust the nozzles up/down & forward/back for when you have many different bottle types and you need to quickly adjust height and depth of the nozzle several times a day.

- Bottle Positioning Rail - Adjustable rail integrated into the front feet, allowing quick positioning of bottles as well as reducing time moving bottles along in front of the machine.