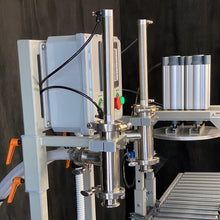

The N500 nozzle is our standard no-drip nozzle that comes included with our pail, drum, and tote filling machines. This nozzle is ideal for water and oil based products and most solvents. Choose between versions for non-food products or food & beverage fluids. Available with sanitary clamp 1.5" (1.984" flange OD) or 2.0" (2.516" flange OD) supply hose connections.

The nozzle orifice is fitted with a flow screen to produce a smooth downward flow of fluid into your container to reduce splashing and sloshing, making the N500 nozzle suitable for filling from above the container opening.

If you require filling from below a container opening, such as filling a closed-head drum or carboy pail, please contact us for lance extension options.

Pair with our XPG and DC line of pail, drum, and IBC tote filling machines.

Availability - Ships in 2-4 weeks, Ships free to US and Canada

Features & Specifications:

- Adjustable open & closing speed

- Pneumatically operated with internal cut-off piston

- Sanitary clamp 1.5" (1.984" flange OD) or 2.0" (2.516" flange OD) supply hose connection

- Nozzle orifice flow screen helps to direct flow and reduce splashing & sloshing. Various flow screen designs available for high viscosity fluids, cone shaped flow, etc.

- Approximate max flow rate of 60 gallons per minute

- Max temperature:

- Food & beverage version: 150°F (66°C)

- Non-food fluid version: 100°F (38°C)

- Wetted materials:

- Food & beverage version: polyurethane, PTFE, buna-N, and stainless steel

- Non-food fluid version: polyurethane, PTFE, buna-N and/or Viton, polymer composite resin, and stainless steel

Available with a lance extension, with or without external foot valve, upon request

Compatible filling machines: XPG-100, XPG-200, DC-100

N500 Nozzle Assembly Includes:

- N500 nozzle assembly

- Orifice flow screen

Alternative designs, including nozzle tip diameter/extension, orifice flow screen designs, max flow rate, and additional sanitary fittings and adapters available upon request.